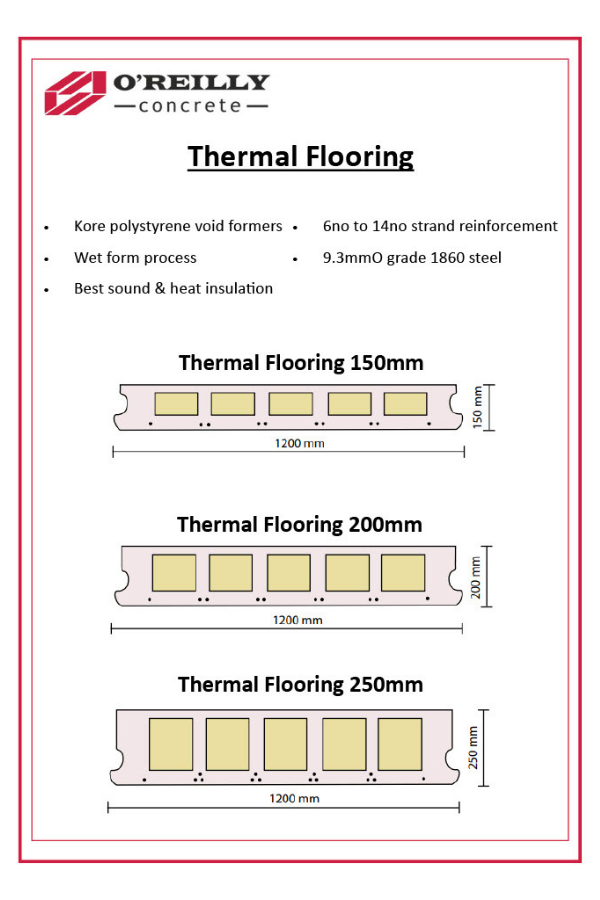

Thermal Flooring

O’Reilly Concrete hollowcore thermal floor slabs are prestressed concrete elements with continuous longitudinal voids formed using polystyrene void formers

Our thermal flooring is manufactured to exact site dimensions with pre-formed service openings where required. The range of depths and achievable spans cover all types of residential houses and most commercial, public and industrial builds. Up to 500m2 of hollowcore flooring can be installed per day.